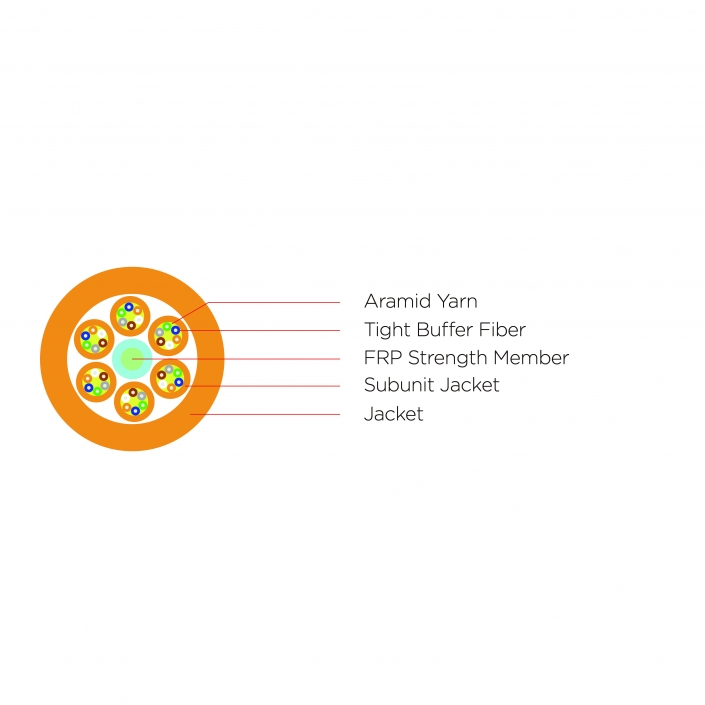

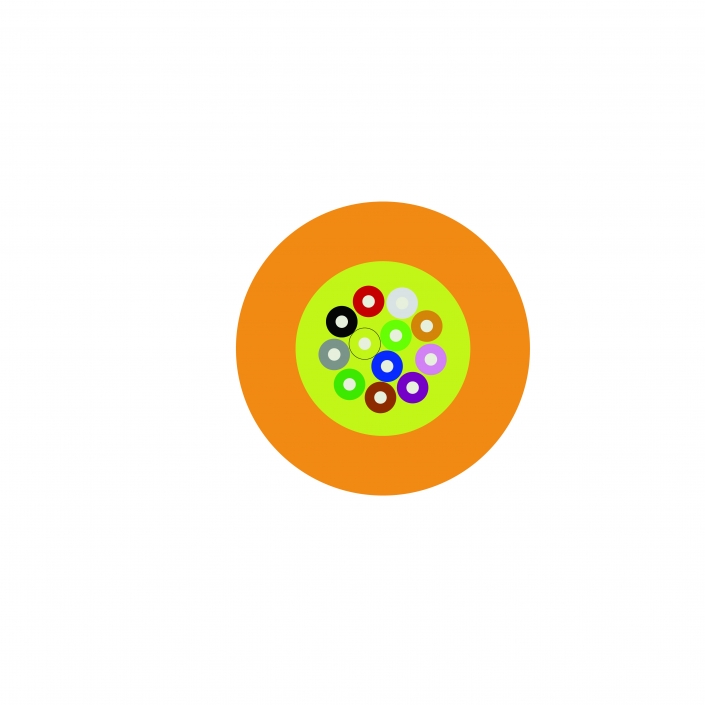

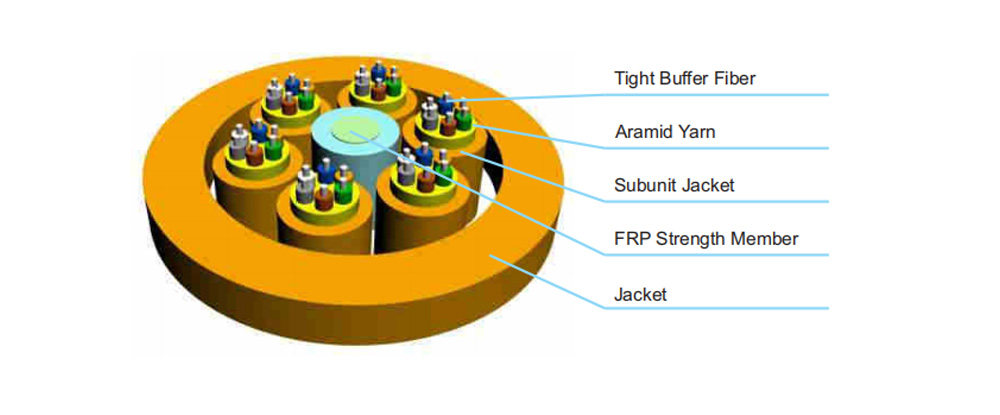

MPC Multi-Purpose Distribution cable use multi-fifiber subunits (Φ900µm tight buffer fifiber, aramid yarn as strength member). A fifiber reinforced plastic (FRP)locates in the center of core as a non-metallic strength member.The subunits are stranded around the cable core. The cable is completed with a PVC or LSZH (Low smoke, Zero halogen, Flame-retardant) jacket.

Characteristics

- Stranded non-metallic strength member structure ensure the cable ensure larger tensile strength.

- Tight buffer fiber have excellent flame-retardant performance.

- Aramid yarn as strength member make cable have excellent tensile strength . The outer jacket material have many advantages such as anti-corrosion, nti- water, anti-ultraviolet radiation, flame-retardant and harmless to environment etc.

Standards

- Comply with Standard YD/T 1258.4, ICEA-596, GR-409, IEC 60794-2-20/21, etc; and PVC cable meet he requirements of UL approval OFNR and FNP.

- Different LSZH jacket meet IEC 60332-1 or IEC 60332-3C.

Temperature Range

- Operating : -40ºC to +70ºC

- Storage : -50ºC to +70ºC

- Installation : -30ºC to +70ºC

- Bending Radius: Static 10D Dynamic 20D

- Indoor any purpose cable distribution.

-

Backbone distribution cable in a building.

-

Multi optical fifiber jumper.

Optical Characteristics:

| Fiber Type | Attenuation | Overfilled Launch Bandwidth | Effective Modal Bandwidth | 10Gb/s Ethernet

link length |

Min Bending Radius | |

| Conditions | 1310/1550nm | 850/1300nm | 850/1300nm | 850nm | 850nm | |

| Unit | dB/km | dB/km | MHZ.km | MHZ.km | m | mm |

| G652D | 0.36/0.22 | 16 | ||||

| G657A1 | 0.36/0.22 | 10 | ||||

| G657A2 | 0.36/0.22 | 7.5 | ||||

| 50/125 | 3.0/1.0 | ≥500/500 | 30 | |||

| 62.2/125 | 3.0/1.0 | ≥200/500 | 30 | |||

| OM3 | 3.0/1.0 | ≥ 1500/500 | ≥2000 | ≥300 | 30 | |

| OM4 | 3.0/1.0 | ≥3500/500 | ≥4700 | ≥550 | 30 | |

| BI-OM3 | 3.0/1.0 | ≥ 1500/500 | ≥2000 | ≥300 | 7.5 | |

| BI-OM4 | 3.0/1.0 | ≥3500/500 | ≥4700 | ≥550 | 7.5 | |

Structure and Technical Specification:

| Fiber

Count |

Cable

Diameter (mm) |

Cable Weight(Ref)

(kg/km) |

Tensile Strength

(N/100mm) |

Crush Resistance

(N/100mm) |

|||

| PVC Jacket | LSZH Jacket | Short Term | Long Term | Short Term | Long Term | ||

| 24 | 12.3±0.5 | 117 | 124 | 660 | 200 | 1000 | 300 |

| 36 | 14.5±0.5 | 171 | 180 | 660 | 200 | 1000 | 300 |

| 48 | 14.8±0.5 | 161 | 170 | 1320 | 400 | 1000 | 300 |

| 72 | 17.5±0.5 | 244 | 254 | 1320 | 400 | 1000 | 300 |

| 96 | 20.7±0.5 | 351 | 366 | 1320 | 400 | 1000 | 300 |

| 144 | 24.8±0.5 | 443 | 451 | 1320 | 400 | 1000 | 300 |

Related Products